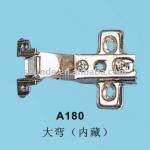

Customized Zinc alloy die casting hinges - 0304

Customized Zinc alloy die casting hinges, 1.Zinc alloy, 2.die casting proces, 3.Apply to refrigerator and oven, 4.OEM service - details see: https://www.furniturepopular.com/customized-zinc-alloy-die-casting-hinges-10038763

| Type: Furniture Hinge | Place of Origin: Zhejiang China (Mainland) | Brand Name: IDEAL HINGE | Model Number: 0304 |

| Product: Customized Zinc alloy die casting hinges | Material: Zinc alloy | Surface treatment: Chrome finish | Feature: Perfect surface effect,good quality |

| Advantage: We can make drawing,moulds,produce and assemble | Shipment: By sea or air, or express | Package: usually in pp bags and then 6 pcs small carton and then big cartons | Delivery: Prompt |

| Quality: Guaranteed | Output: 20000pieces/month |

Customized Zinc alloy die casting hinges

Let us take a look at one die casting hinge how do we produce them:

1.Talk about all the details and make the drawing

2.make moulds

3.Produce and polish the the die casting hinge

4.Chrome surface treatment

5.Assemble the hinge

6.The assembled die casting hinge

We are a die casting factory,we could customized all kinds of hinges and also other die casting parts.

| Types | Cold Chamber Die Casting and hot chamber die casting | ||||||

| Produce process | Drawings→mould making→pre-forging→rough machining or finish machining→surface treatment→product checking→packing→delivery | ||||||

| Material available | aluminum, zamak,brass, aluminum alloy,zamak alloy and so on | ||||||

| Surface treatment | sandblast, anodized, galvanization, powder coating, baking varnish etc | ||||||

| Precision CNC | turning, milling, drilling, wire EDM, welding, casting, forging, assembling, etc | ||||||

| Capacity | from small to large,the size will depend on your drawing | ||||||

| Die casting moulds | Material:H13,DIEVAR,QDN,8407,2344V,TQ1,2343,SKD61,45#steel,etc. | ||||||

| Cavity:single or multi | |||||||

| Size:depend on your product need to be made | |||||||

| Quality control | ISO9001:2000 certificated | ||||||

| Production capacity | depend on parts | ||||||

| Design ability | CAD, UG, Pro/E, JSCAST-v8 of Japan, FLOW3D.v9.2 of America, etc. | ||||||

| Experience | 10 years of professional CNC machining service | ||||||

| Packaging | standard export carton with pallet or as per customes'requirement | ||||||

| Lead time | making arrangement according to customers'request | ||||||

| Term of Payment | T/T, L/C, western union, Escrow,PayPal | ||||||

Hi Friend,

Come here to complete your great idea,

Or complete your OEM/ODM complicated product.

We give you the best solution!

| Packaging Detail:Usually we pack them in PP bags separately,and 6-8 pcs in one small cartons.And then put the small cartons into big cartons to deliver them. |

| Delivery Detail:around 15 days to make the mould and one month for 20000 pcs |