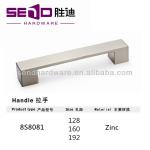

Aluminum and zinc alloy die casting furniture handle - KM-DC-086

Aluminum and zinc alloy die casting furniture handle, 1.ISO9001, 2.High-class quality, 3.Professional design, 4.OEM ODM - details see: https://www.furniturepopular.com/aluminum-and-zinc-alloy-die-casting-furniture-handle-10039227

| Type: Furniture Handle & Knob,Aluminum and zinc alloy die casting furniture handle | Place of Origin: Guangdong China (Mainland) | Brand Name: KingMetal | Model Number: KM-DC-086 |

| Material: Aluminum | Usage: Cabinet,Drawer,Dresser,Wardrobe | Item: Aluminum and zinc alloy die casting furniture handle |

Present Product information

| Product name | Product No. | Material | Weight | Surface treatment | Application |

| aluminum zinc castings and die castings for handle | NY--932 | Zinc | 50g | Plating | Furniture |

The thing mostly customer care about

MOQ:1000die

Zinc Mold life:normally 100,000die

Payment:about mould pay the 50% after design confirm,pay the remain after sample confirm within 1-3days since receive;about product pay 50% after sample confirm,pay the remain before delivery.

Delivery time:in general about mould for 20-30days,about product for 10-30days.

| Overall product information | |

| Material | A360, A380, A383,ADC10,ADC12 , ,AL6061,AL6063 , AL7075,ZL104, ZL107; Zamak 3, Zamak 4, Zamak 5or others |

| Available weight of product | From 0.005kg to 25kg |

| Applied software | PRO/E, Auto CAD , UG, |

| Secondary processing | CNC turning,lathe machining, Drilling, tapping, over sand, |

| Surface Treatment | Plating, Sandblasting, oil Painting, Powder Coating,plating ,Anodizing(only silvery for die casting aluminum ),oxidation(onlyblack,silvery for die casting aluminum). |

| Products application | Office equipment parts ,Motor Parts,Furniture Parts,Light fittings,Communications equipment ,etc |

| Available service | Mold manufacturing, zinc\ aluminum production, product processing (drilling, tapping, remove burr lathe machining) Surface treatment: powder, fuel injection, electroplating, oxidation, sand blasting |

| Package | Cartons, wooden boxes or others |

| Delivery | Mold manufacturing time:20 to 30days, die casting product time:10-30days. |

| Packaging Detail:polybag + soft foam bag / inner box / master carton. |

| Delivery Detail:20 days |